At Northwestern University, state of the art facilities in material research shown below will be integrated into the the Center for UAS Propulsion.

ARPI description

The Additive Rapid Prototyping Instrument (ARPI) was developed for the rapid realization of products epitomized by multi-material structures and multi-scale features. ARPI is a multi-functional modular system composed of three subsystems (primary AM processing, secondary operations, and monitoring), each of which can function either in a stand-alone or integrated manner in a common command-and-control environment. ARPI provides an integrated processing platform and environment for enhancing part accuracy, surface finish, and material properties beyond the current capabilities of additive manufacturing. ARPI can be viewed as an advanced multi-functional 3D manufacturing platform offering the capability of future expansion as it is an open architecture instrument, easily reconfigurable for the exploration of new ideas.

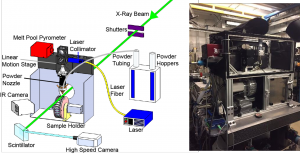

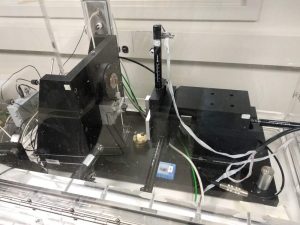

Argonne DED Experimental Setup

This high-speed DED machine was created to enable in-situ X-ray imaging during multi-layer deposition. This portable machine can be placed within the Argonne National Laboratory Advanced Photon Source beam line for in-situ X-ray imaging to be preformed. In addition to X-ray imaging, the experimental rig features melt pool monitoring and part-scale thermal monitoring. Capture of high-speed X-ray images allows for visualization of additive manufacturing phenomena such as Marangoni flow, porosity formation, phase contrast and solidification.