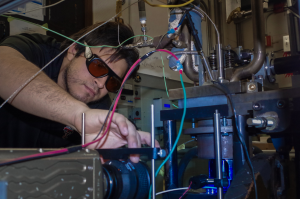

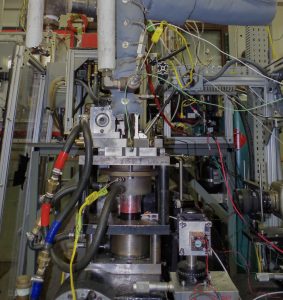

Compression-Ignition Optical Engine Laboratory (UW-Madison)

This laboratory features a compression-ignition direct-injection optical engine which enables direct observation of fuel injection and combustion events. The engine geometry is modeled after a light-duty automotive diesel engine with a nominal compression ratio of 14:1. Peak compression temperatures and pressures before combustion can be varied in the range from 800 to 1100 K and 5 to 85 bar using air or pure nitrogen as the intake charge gas. The design of the engine is modular, and can be adapted to a number of fueling/combustion strategies using both liquid and gaseous fuels. Two high-pressure fuel system are available to pressurize common-rail diesel injection systems. Primary imaging access, enabled by a Bowditch piston extension, is through a UV-grade fused silica piston crown which allows the entire piston bowl volume to be imaged. An additional set of windows, positioned in the upper portion of the cylinder liner, provide laser sheet access for planar laser-based imaging diagnostics. The lab is equipped with several high-speed digital imaging systems which can be operated concurrently allowing multiple simultaneous optical diagnostics to be applied to a single combustion/injection event. Multiple Nd:YAG laser systems are available for pulsed laser imaging, including a pulse-burst laser system capable of repetition rates > 50 kHz. Imaging diagnostic capabilities include: natural luminosity imaging, schlieren imaging, shadowgraph imaging, intensified spontaneous OH chemiluminescence imaging, particle image velocimetry (PIV) formaldehyde planar laser-induced fluorescence (PLIF) imaging, OH PLIF imaging, tracer-based PLIF imaging, and several laser-based planar temperature imaging techniques.

Transient Multi-Cylinder Engine Laboratory (UW-Madison)

This laboratory features an automotive four-cylinder common-rail compression-ignition direct-injection engine, General Motors/Fiat JTD 1.9 L, coupled to a low inertia transient dynamometer. The engine can be run in different configurations, with either low or high pressure EGR loops and with or without cylinders deactivated. The setup features real-time engine control and integrated low-speed and high-speed data acquisition. High-speed pressure data can be acquired simultaneously from all four cylinders along with high-speed emissions data. Two of the engine cylinders are outfitted with laboratory grade piezoelectric pressure sensors while the remaining cylinders feature pressure sensing glow plugs. Crank-angle resolved emissions are measured with fast flame ionization detectors (FIDs) for hydrocarbons and fast chemiluminescence detectors (CLDs) for nitric oxides, both sampling in a close coupled arrangement. Low-speed emissions data are measured with a Fourier transform infrared spectrometer (FTIR), an opacimeter, and a smoke meter. This laboratory was established to study a wide range of engine operating conditions ranging from low-speed cold start conditions to high-speed high-load conditions for a range of conventional and advanced combustion strategies.